Automated Multi-Objective Pedicle Screw Planning

As surgical guidance systems become increasingly common in spinal fusion procedures, there is a growing need for detailed virtual planning of the screws to be placed. Current planning methods rely heavily on manual processes that are time-consuming and do not fully leverage patient-specific anatomy for precise pedicle screw placement.

Limitations of Manual Planning

Traditional pedicle screw planning faces several inherent limitations:

- Time and cognitive burden: Manual planning is labor-intensive and mentally demanding.

- Screw stability: The heterogeneous bone structure within vertebrae creates significant variations in mechanical strength, but human planners cannot easily leverage these density differences.

- Rod contouring complexity: Poorly aligned screw heads require extensive rod bending, which can weaken the construct and complicate surgery.

Our Automated Planning Pipeline

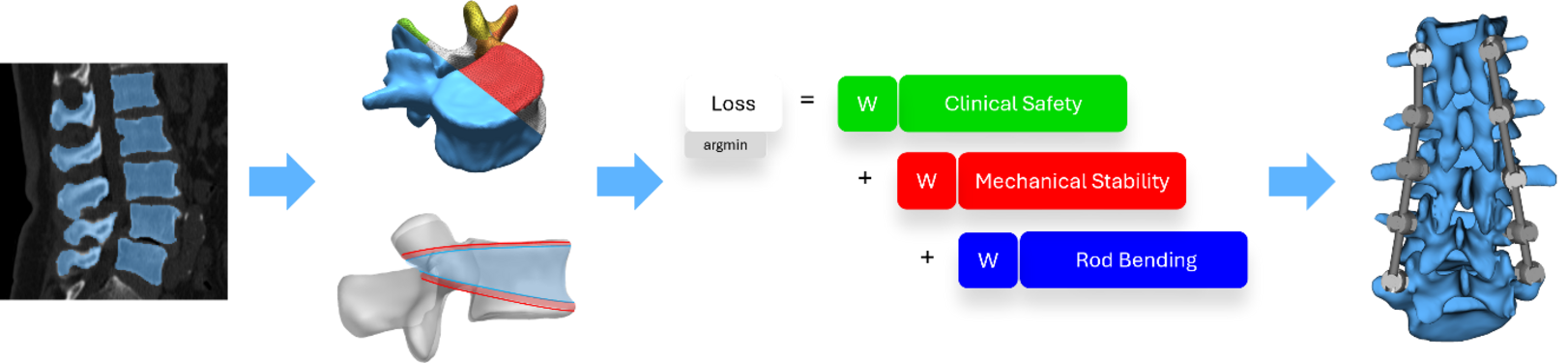

We developed a pipeline for automated pedicle screw planning based on CT. A neural network first identifies and segments the vertebrae and a novel surface fitting algorithm serves to identify specific anatomical regions to identify the corridor of safe screw placement. A multi-objective optimization framework then identifies the screw plan that yields the best balance of clinical safety, biomechanical stability and screw head alignment.

A detailed analysis of the pipeline suggested that it consistently generates clinically feasible screw plans combined with improved mechanical stability and screw head alignment when compared to manually created plans.

Figure 1: Schematic overview illustrating the main components of the automated pedicle screw planning pipeline, comprising segmentation, template mesh fitting and permissible zone delineation, optimization function and generated surgic